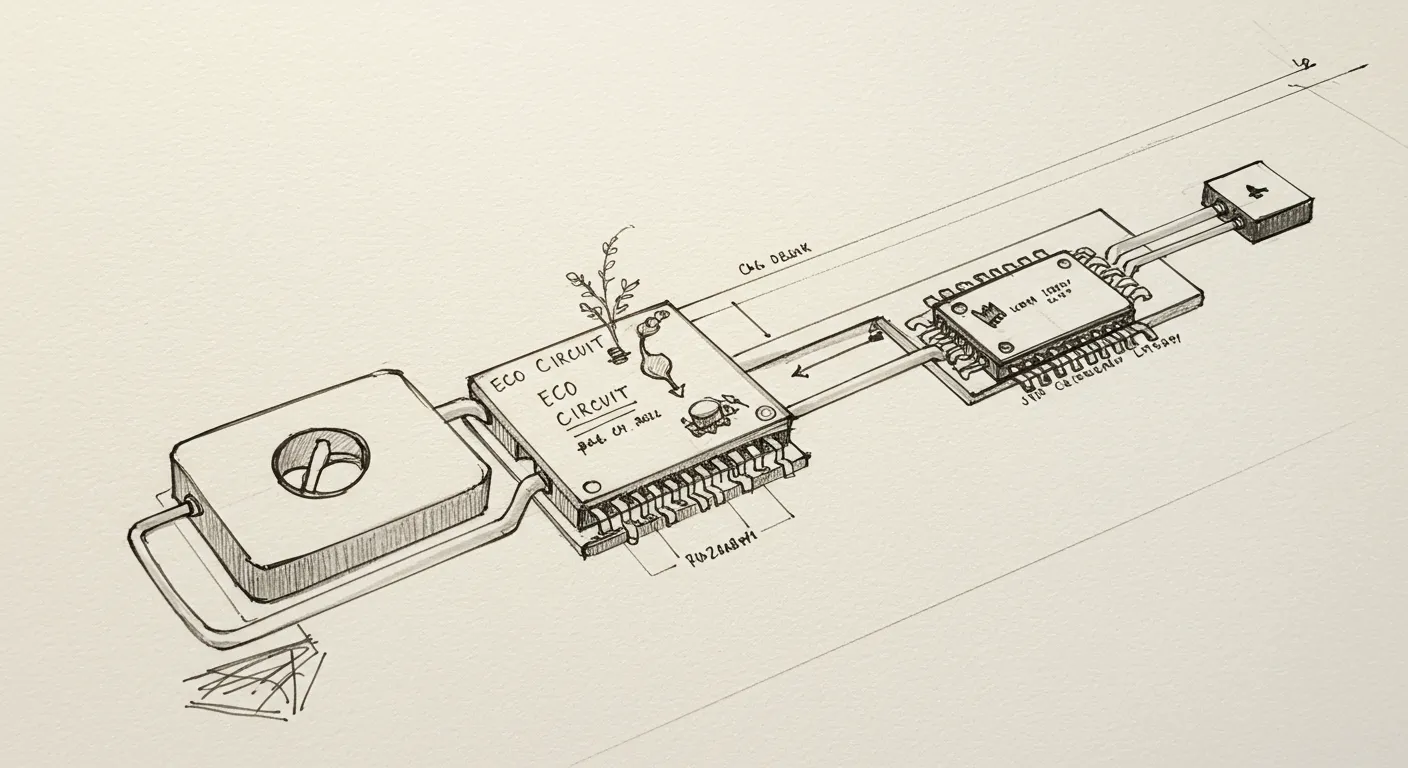

In the world of electronics, sustainability is slowly creeping into traditionally chemical-heavy domains. Arduino's latest venture into bio-based printed circuit boards (PCBs) represents a promising yet complicated frontier of green technology.

Online commentators are already dissecting the technical challenges. The core issue revolves around material performance: while bio-based substrates like PLA offer environmental advantages, they struggle with fundamental engineering requirements. Heat resistance emerges as a critical stumbling block, with one commentator bluntly noting that PLA becomes practically useless above 60°C – a temperature easily reached inside a parked car.

The technical skepticism isn't dismissal, but a pragmatic assessment. These bio-based PCBs aren't ready for mainstream electronics, but they represent an important experimental pathway. The research suggests a future where sustainable materials might gradually improve, potentially disrupting traditional PCB manufacturing.

Arduino's approach seems to be less about immediate replacement and more about exploring technological boundaries. By pushing the limits of bio-based materials, they're creating a blueprint for future innovations that could eventually merge ecological considerations with robust engineering performance.

The broader narrative isn't just about a single product, but about reimagining how we construct fundamental technological components. It's a microcosm of a larger trend: industries slowly but persistently exploring how to make core manufacturing processes more environmentally responsible.